Actualités

Alertes sécurité du CERT – 14/10/2024 – Risques Cyber de la semaine : Ivanti – Schneider Electric – Adobe – Microsoft – Mitel – Palo Alto – Synology – GitLab – Mozilla

Veuillez trouver le bulletin d’actualité du CERT du 14 octobre reprenant : Vulnérabilités significatives de la semaine 41 TABLEAU RÉCAPITULATIF : Vulnérabilités critiques du 07/10/24 au 13/10/24 Editeur Produit Identifiant CVE Score CVSSv3 Type de vulnérabilité Date...

Réponse à impact à haute vitesse et comportement en compression après impact des composites thermoplastiques en fibres de carbone continues

Résumé synthétique : Cet article explore la résistance aux impacts et la tolérance aux dommages des composites thermoplastiques en fibres de carbone continues (CCFRTP) via des tests d'impact à haute vitesse (HVI) et de compression après impact (CAI). Les résultats...

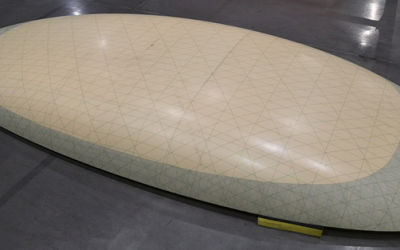

Airbus Atlantic met en avant son expertise en structures aéronautiques composites

Résumé synthétique : Airbus Atlantic présente un concept de radôme en fibres de carbone et de quartz à JEC World 2024, conçu pour des essais en vol. Le projet illustre son expertise dans les structures composites complexes. Airbus Atlantic combine des technologies...

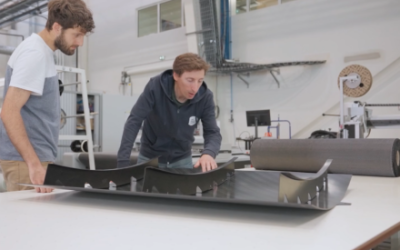

Clôture du projet SPECTRA : une avancée majeure pour le soudage par conduction dans l’aéronautique

Le projet SPECTRA piloté par l’IRT Jules Verne vient de se conclure, marquant une étape significative dans le domaine du soudage par conduction des structures aéronautiques. Ce projet a rassemblé différentes compétences et savoir-faire, réunissant des acteurs de...

Optimisation de la qualité de surface des composites thermoplastiques : une approche novatrice pour réduire les défauts de zones sèches dans le moulage de structures multi-prismatiques

Résumé synthétique : Cette étude traite de l'optimisation du moulage des composites thermoplastiques renforcés en fibres continues (CFRTP), notamment en réduisant les défauts de zones sèches lors de la formation de structures complexes. En ajustant deux paramètres...

Analyse de la thermographie infrarouge pour la caractérisation rapide de la fatigue des composites thermoplastiques renforcés de fibres courtes

Résumé synthétique : Cette étude explore l'utilisation de la thermographie infrarouge (IRT) pour caractériser rapidement la fatigue des composites thermoplastiques renforcés de fibres courtes. En comparant les méthodes traditionnelles et IRT, cette dernière a montré...

«Si Starship fonctionne vraiment, SpaceX écrasera la concurrence en termes de prix», estime Paul Wohrer, chercheur à l’Ifri

Au-delà de l'exploit technique réalisé en récupérant parfaitement sa fusée Starship le 13 octobre dernier, SpaceX pourrait révolutionner le marché des lancements des satellites. De quoi fragiliser l’industrie spatiale européenne. L’avis de Paul Wohrer, chercheur à...

Le projet ECARE, financé par Clean Aviation, lance sa nouvelle plateforme numérique

La décarbonation de l’aviation nécessite des travaux de R&D importants et il est important de mobiliser les acteurs du financement public de l’aéronautique pour soutenir le développement de cette feuille de route technologique ambitieuse. Missionné par...

Clean Sky 2 : Un fuselage révolutionnaire en thermoplastiques pour des avions légers et écologiques

Clean Sky 2 est un partenariat public-privé ambitieux soutenu par l'UE, dont l'objectif principal est de contribuer à réduire les émissions de CO2, d'oxydes d'azote et de bruit des avions jusqu'à 30 %, conformément au Pacte vert qui vise, quant à lui, à décarboner...

Impression 3D de l’un des aciers inoxydables les plus résistants

L’impression 3D révolutionne l’industrie manufacturière, mais son application aux alliages métalliques complexes reste un défi technique majeur. Des chercheurs se sont récemment concentrés sur la production d’un acier inoxydable particulièrement résistant, le 17-4...