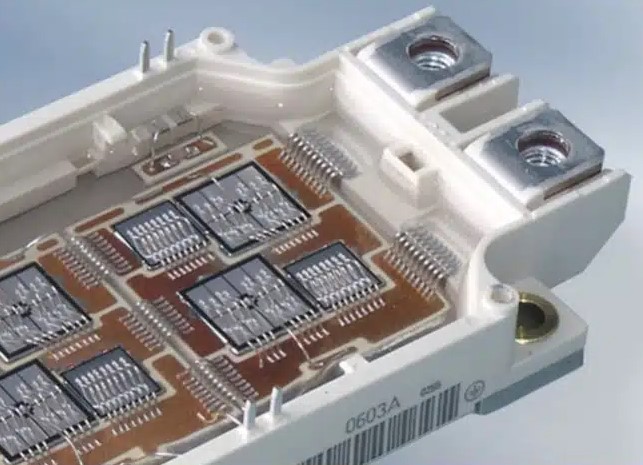

This paper presents a novel thermal management approach for power semiconductor modules by integrating active liquid cooling directly into the substrate. Utilizing Direct Bond Copper (DBC) structures embedded within liquid cold plates, the method minimizes thermal interfaces, improves power density, and ensures better reliability. It contrasts traditional multi-interface cooling paths with an integrated monolithic solution that embeds the coolant flow directly under the semiconductor die using proven manufacturing techniques.

Introduction and Motivation

The push toward electrification across transportation — rail, marine, aviation, and ground vehicles — brings significant benefits such as lower emissions, quieter operation, and reduced dependency on fossil fuels. However, it also places higher demands on power electronic systems, requiring efficient thermal management to handle increasing power densities. Emerging wide-bandgap semiconductors, like Gallium Nitride (GaN) and Silicon Carbide (SiC), are highly efficient but introduce thermal challenges due to smaller die footprints and higher heat flux. To mitigate this, active cooling systems such as pumped liquid cooling are deployed. This method provides more precise temperature control compared to passive or forced-air cooling, thereby enhancing the reliability and performance of systems operating in extreme environments.

Pour en savoir plus : Direct-Die Liquid Cooling: A Scalable Approach for Power Module Thermal Integration