12 01 2026 | Actualité Défense et Sécurité, Actualité Spatial, Innovation et technologique

Advanced thermal protection systems (TPS) company Blueshift (Spencer, Mass., U.S.) has uncovered a heightened risk of collision from falling space debris as a result of a decade-long growth in satellite launches, which has intensified the demand for improved safety,...

15 12 2025 | Innovation et technologique

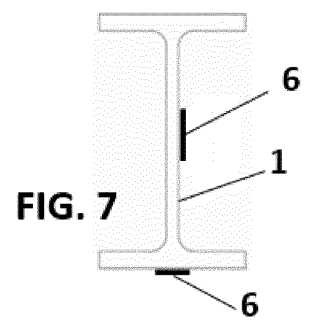

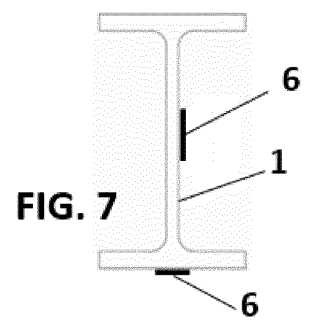

The present invention relates to a glass fibre reinforced plastic (GFRP) profile having a uniform section formed by means of a thermoplastic material bonded with glass fibre by means of a pultrusion method and incorporating at least one carbon fibre reinforcement (6)...

15 12 2025 | Innovation et technologique

The aerospace sector continually demands advanced, multifunctional materials capable of enhancing performance, reducing structural weight, and improving fuel efficiency while ensuring exceptional integrity, durability, safety, and environmental sustainability. The...

15 12 2025 | Innovation et technologique

Recent comprehensive research (2023–2024) on basalt fiber-reinforced composites (BFRCs) has meticulously documented significant progress across diverse applications, including protective coatings, high-performance concrete, reinforcement bars, and advanced laminates....

15 12 2025 | Innovation et technologique

Pour répondre aux contraintes économiques et environnementales, l’industrie aéronautique s’oriente vers des composites thermoplastiques recyclables, plus faciles à assembler et plus résistants aux chocs thermomécaniques que les composites thermodurcissables. Des...