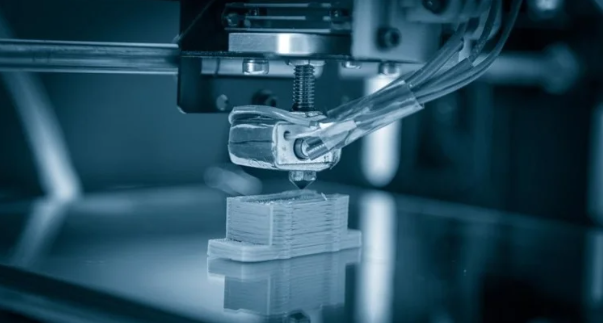

Many attempts have been made to transition the mode of production from conventional manufacturing to AM for a number of materials, including structural ceramics, polymers, alloys, and various functional materials. Due to its rapid production rates, powder self-support, wide material compatibility, and capacity to accomplish large-scale and high-volume production, binder jetting additive manufacturing (BJAM) is considered to be one of the most promising AM technologies for industrial applications. The ina

Source : Binder Jetting Additive Manufacturing for Industrial Applications